Step 1

Screening

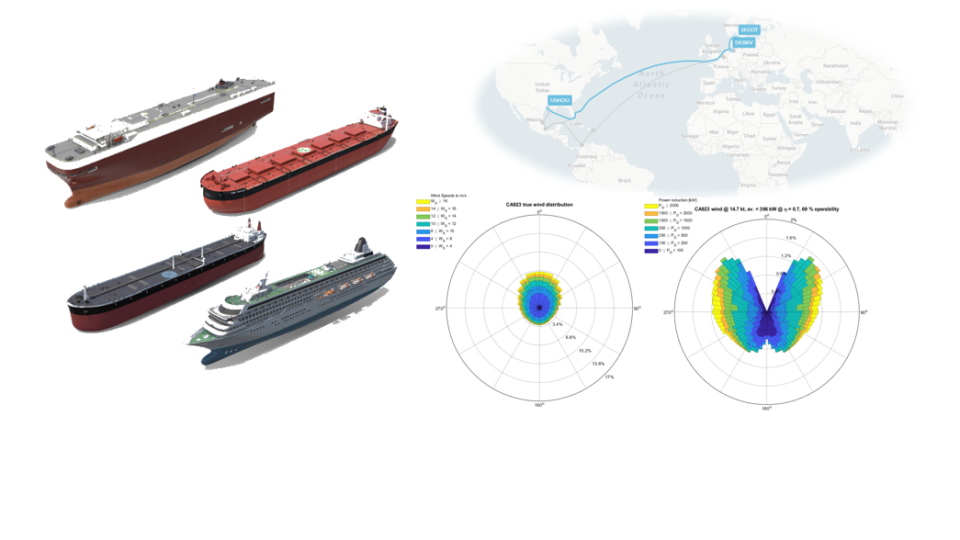

Selecting the vessel

First step is selecting an appropriate vessel in the existing fleet or the newbuilding program. One or several appropriate vessel candidates are selected based on their operational profiles, age and general arrangements. If a vessel has an upcoming dry-docking, that could be a good opportunity to install a wind-assisted propulsion system.

The wing sail can be moved and used on another vessels, but you might not want to do extensive steel strengthening in the hull if recycling is just a few years away. On the other hand, it can be a way to avoid stranded assets by keeping an older vessel in operation instead of taking out of operation too soon.

Analyzing the route

Oceanbird´s performance analysis team investigate the weather conditions along the route of the selected vessel. They investigate the statistical distribution of wind speed and direction, together with other ship and weather-related parameters. The conditions for each leg of the route are being visualized and the team concludes whether it is a favorable route or not. The savings in terms of propulsion power, fuels and emissions is presented to the owner.

It could be a good idea to dedicate a vessel with wind propulsion to a favorable route, but it can also work in the regular system.